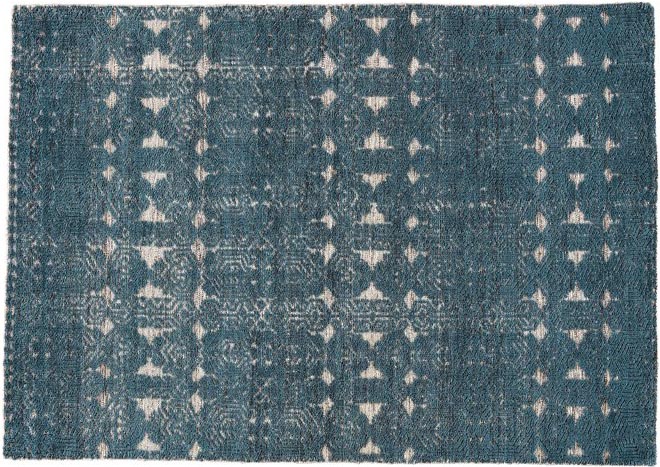

Fueling the practice of an ancient art

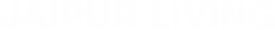

Four artisans take up to eight months to hand-knot a single Jaipur Living rug. At the end of that time, and about 2.3 million knots later, the back of the rug is covered with extra fibers and lint that could distract from the pattern. To create a pristine surface, the next step is to burn off unwanted fibers—a key step, and a leap of faith. As one rugmaker describes it, it’s a defining moment in a rug’s creation, or the chance for it all to go up in flames.

Raw wool is transformed into beautiful pieces of handwoven art through multiple steps, including the high-temperature burning that efficiently cleans the reverse side of plush weavings.

Four artisans tie 2.3 million knots over eight months to make one Jaipur Living rug—a lot to risk under the flame of a fire.

Simple, essential steps: Scrub, then burn

Our artisans prepare a rug with a thorough hand-washing before the burn. Next, liquefied petroleum gas (LPG) is brought in to provide steady, clean-burning heat at 3,000°F. The only equipment needed is an LPG container, a gas pipe and a nozzle. The rug, now completely free of dust and other particles that might create an uneven effect in the burning process, is unrolled in a well-ventilated area and has a flame applied to its surface from end to end. After the burn, incinerated fibers are scrubbed off with a brush specially made for the task, using dried palm tree barks and leaves.

According to tradition, burnt fibers are removed using a brush that is handmade out of dried palm trees.

Confidence through Experience

There is no specific timing or approach for how a rug surface is burned; it’s an art that’s been mastered over time by people who know exactly how much flame to apply, where and for how long (of course, carefully avoiding all tassels and adornments woven into the rug).

And much like bold, unique approaches to design, there’s an instinct that makes each burn different every time, drawing on experience to know when to back off—and when to turn up the heat.

Next story